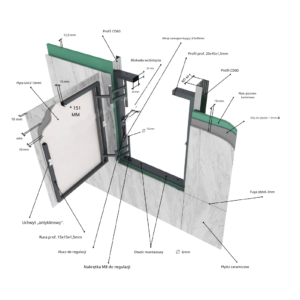

Inspection hatches are mainly used for comfortable access to technical communications, ranging from plumbing taps, filters and meters, to pumps, siphons and boilers, elements that require systematic inspection access, maintenance and repair.

To preserve the design, in residential premises, plumbing communications are hidden in bathrooms, in rooms that are mainly tiled with ceramic tiles, such as a bathroom, toilet, boiler room. The pressure hatch is used both outside and indoors, as well as in rooms with high humidity.

Technical characteristics of the inspection hatch for tiles.

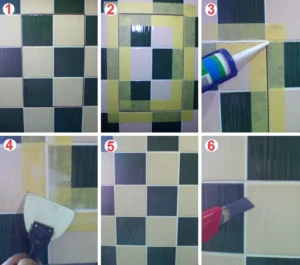

The inspection hatch for tiles has the main feature, thanks to the unique design mechanisms – the hatch, when installed in the opening, facing with ceramic tiles and sealing the seams with silicone sealant, creates the effect of 100% invisibility of the hatch ( invisible hatch ) against the background of decorative finishing, which in turn is important aspect when renovating premises.

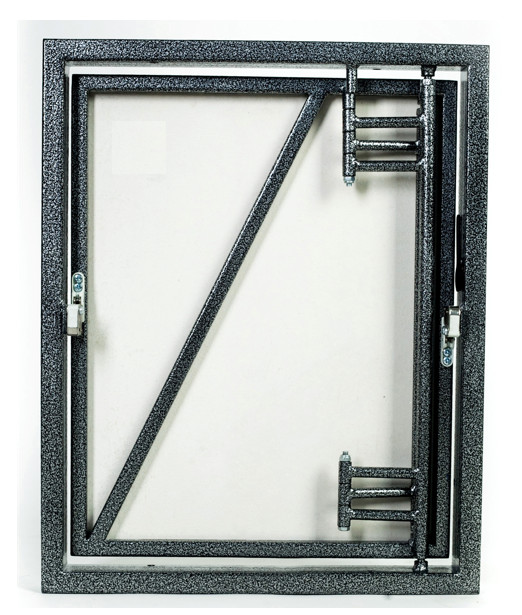

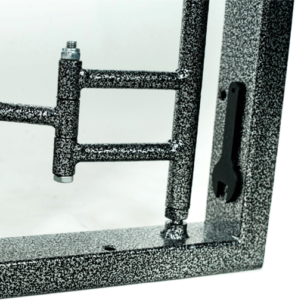

Push hatches gained their versatility thanks to push locks, with the help of which the hatch under the tiles is closed and opened by lightly pressing the door; this advantage allows you to line the push hatch with any finishing material. Our Mini-Latch model push locks have a guaranteed service life of 20,000 cycles; if you open the hatch every day, the locks will last you 55 years. Another unique feature of our push locks is their anti-wedge holders, which, in case of jamming of the lock, still allow you to open the hatch door.

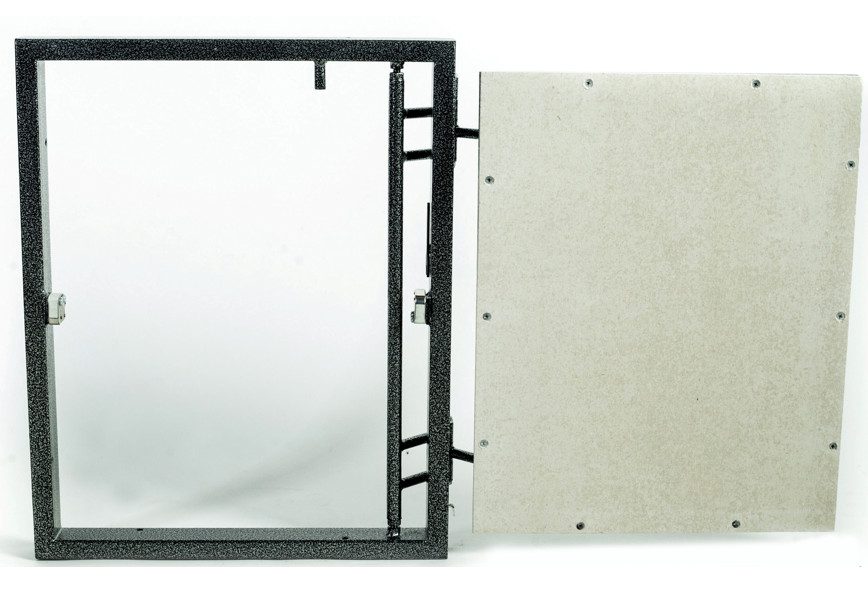

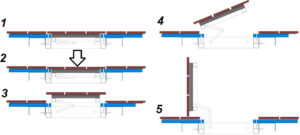

The uniqueness of the design of swing hatches is focused on two-link, non-sagging adjustable hinges of the hatch, thanks to which all the gaps between the tile seams will be maintained for the entire service life of the hatch. Also, due to its technical capabilities of a two-link hinge, the hinged hatch door opens in a special way, without chipping the edges of adjacent tiles, which is very important with millimeter-thick seams between the tiles.

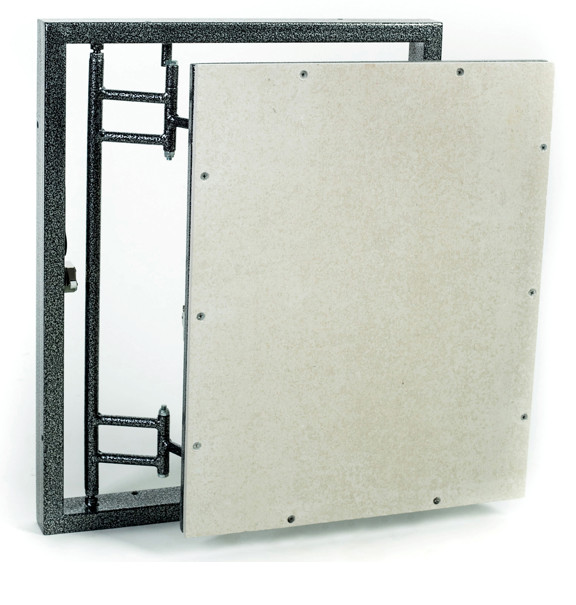

All hatches for tiles of our production are equipped with a GVLV plate (moisture-resistant gypsum fiber sheet), which is screwed to the hatch door and acts as a plane for facing with ceramic tiles or mosaics. The characteristics of GVLV boards ( supersheet ) exceed the quality indicators of all analogues, both in increased strength and moisture resistance. To tile a hatch, it is enough to prime the surface of the GVLV slab.

For a longer service life in wet rooms, all metal parts of our hatches are painted with anti-corrosion hammer enamel , which in turn not only protects the structure from rust, but also gives the product a unique, beautiful look.

The latest high-precision equipment and the professionalism of our employees allow us to produce hatches of precise geometry and adhere to dimensional accuracy of up to 1 millimeter , which is very important when facing with ceramic tiles. Also, the company’s production capabilities allow us to produce hatches of any size , according to your individual dimensions, in the shortest possible time and in unlimited quantities.

Thanks to many years of manufacturing experience, we are responsible for the quality of our hatches, and with all responsibility we give a 5-year warranty on pressure hatches for tiles.