The sliding inspection hatch is used for all types of tiles and mosaics.

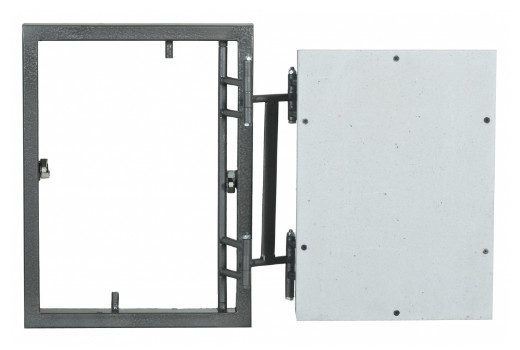

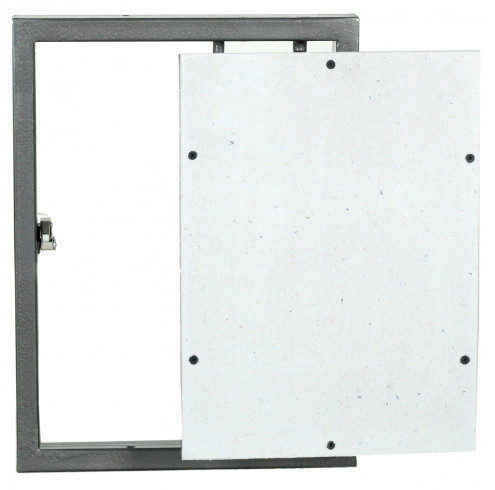

The versatility of the sliding-push hatch lies in the special design of the push locks, which allow you to open the hatch door after light pressure, which in turn makes it possible to use the hatch for a variety of types of finishing materials. The peculiarity of this hatch model is its use in places with difficult access for normal opening. The sliding hatch opens after pressing the door and then moving it to the side parallel to the wall at a distance of 15 cm in which the hatch is installed.

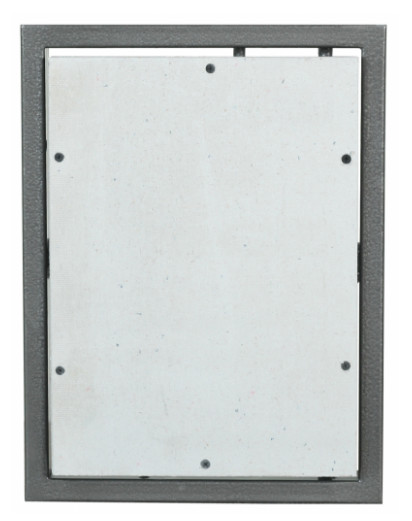

Thanks to the unique technical design mechanisms, the hatch, when installed in the opening and further cladding, creates the effect of 100% invisibility (invisibility) of the hatch against the background of decorative finishing.

The sliding hatch is used in a wide variety of rooms and for a variety of technical tasks. Due to its design capabilities, the main use of the hatch is comfortable access to communication elements, ranging from taps, filters and meters, ending with pumps, siphons and boilers, elements that require systematic audit access, maintenance and repair. Basically, engineering communications are hidden under the lined surface tiles or mosaics, in residential premises this is a bathroom, toilet… Modification of the pressure hatch will provide convenient access for inspection and preserve the aesthetic interior design of the room.

Specification

– Framedoor material : profile steel pipe 40*20*2; 15*15*2; round steel pipe d12

– Door plate : GVLV (moisture-resistant gypsum fiber sheet)

– Accessories : push locks (with anti-wedge holders) “mini-latch”

– Assembly method : argon-arc welding.

– Painting : anti-corrosion powder/hammer

– Opening pattern : swing-sliding door (double two-link hinges)

– Opening/fixing method : pressing

– Installation method : fastening with self-tapping screws/dowels (holes in the frame d6)

– Contents : technical passportwarranty card

Table of standard sizes:

| Hatch dimensions (frame) (WxH mm.) |

Door dimensions (WxH mm.) |

Door load (kg) |

Complete hatch weight (kg) |

| 200×300 |

152×245 |

9 |

2.1 |

| 200×400 |

152×345 |

11 |

2.3 |

| 200×500 |

152×445 |

12 |

2.7 |

| 300×200 |

252×145 |

9 |

2.1 |

| 300×300 |

252×245 |

13 |

2.5 |

| 300×400 |

252×345 |

14 |

3.2 |

| 300×500 |

252×445 |

16 |

3.9 |

| 300×600 |

252×545 |

18 |

4.6 |

| 400×300 |

352×245 |

14 |

3.2 |

| 400×400 |

352×345 |

16 |

3.6 |

| 400×500 |

352×445 |

18 |

4.3 |

| 400×600 |

352×545 |

20 |

5.0 |

| 400×900 |

352×845 |

27 |

10.0 |

| 500×300 |

452×245 |

16 |

3.9 |

| 500×400 |

452×345 |

18 |

4.3 |

| 500×500 |

452×445 |

20 |

6.5 |

| 500×600 |

452×545 |

23 |

7.7 |

| 500×800 |

452×745 |

27 |

10.0 |

| 600×300 |

552×245 |

18 |

4.6 |

| 600×400 |

552×345 |

20 |

5.0 |

| 600×500 |

562×445 |

24 |

8.8 |

| 600×600 |

552×545 |

30 |

12.7 |

| 600×1000 |

552×945 |

32 |

14.0 |

Installation

Installation instructions for the “Sliding” model hatch

1 ) Prepare an opening for installing the hatch. The size of the opening must correspond to the size of the hatch (see table of standard sizes)

2 ) Install the hatch in the opening and align the hatch door plate in the same plane with the main wall.

3 ) Secure the hatch frame in the opening using self-tapping screws or dowels.

4 ) Prime the hatch door slab and glue the tiles or mosaics. The tile protrusion beyond the door is allowed from 5 to 75 mm. with the condition that 60% of the tiles are glued to the door plate.

5 ) After the glue has dried, rub the tile seams, except for the seam along the contour of the door.

6 ) Apply masking tape along the contour of the door seam, and fill the seam with sealant to match the color of the grout.

7 ) Collect the remaining sealant with a spatula.

8 ) After the sealant has dried, remove the tape and cut the silicone seam with a knife blade at an angle of 45 degrees.