Floor hatch for tiles with electric lift, model “Elite”.

The invisible hatch is designed for convenient use when moving between floors, as well as for inspection. This model is designed specifically for indoor use, with an improved hatch design for easy and comfortable use. After tiling, you can walk on the surface of the hatch (withstands more than 500 kg), thanks to which the usable area ofthe room is saved. Another feature of this model is that the hatch, after facing it with ceramic tiles against the background of the floor, is invisible, which is why it is also called an invisible hatch .

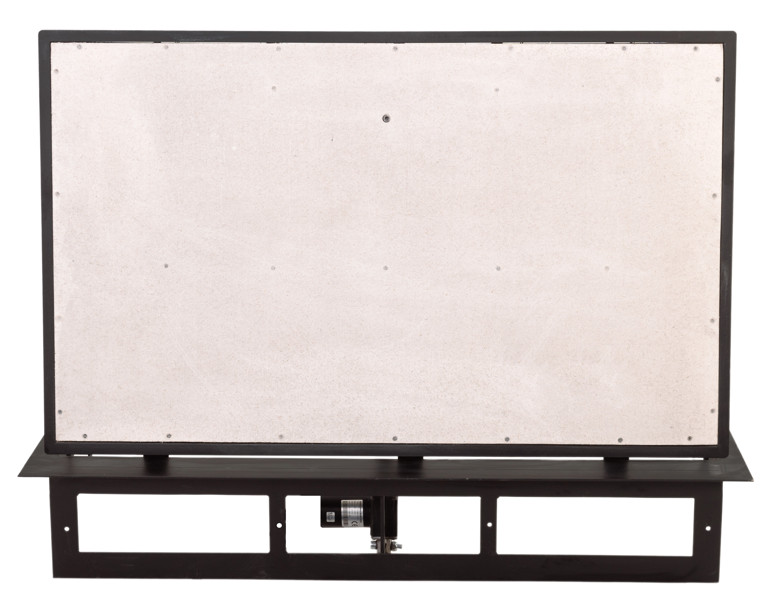

The basement hatch is made of two main parts: the hatch frame and its cover. The design of the product is equipped with an actuator ( electric lift ) that easily lifts a heavy hatch cover with tiles; also, to facilitate the operation of the actuator and distribute the load on the hatch, gas shock absorbers are mounted, which are selected by pressure force and length in accordance with the dimensions of the hatch.

Hatches, for safe opening and to prevent hatch breakage or chipping of tiles, are equipped with electric limit switches that stop the closing/opening of the hatch cover at the desired angle; just press a button – the electric lift will do the job completely safely itself. For comfortable operation, the actuator is equipped with a control unit and three remote controls. The control panel works smoothly despite ceilings or concrete walls.

The electric lift is equipped with a power supply that connects to a 220V network. The control unit is mounted under the hatch; like the remote controls, it is equipped with control buttons for opening the room from below.

Special fastenings of the actuator on the hatch cover provide for adjustment of the pressure of the cover to the hatch frame.

Also, the floor hatch on the electric lift is equipped with an emergency opening system in the event of a lack of electricity or breakdown of electrical equipment.

If necessary, electrical equipment can be equipped with a battery power supply for operation without a 220V network.

The hatches are made from thick-walled rolled metal, which is formed into a structure of the required size using professional electric welding (see technical specifications). All metal parts of the hatches are cleaned and powder coated (baked in a 200 degree oven), which guarantees protection against corrosion of the hatch in rooms with high humidity. A durable and moisture-resistant GVLV slab is attached to the hatch cover, which, after priming, is lined with ceramic tiles. To increase reliability when there is a load on the surface of the slab, the hatch cover is reinforced with stiffeners, in accordance with the dimensions of the hatch and its purpose. For tight clamping and sealing of the hatch, rubber seals are provided along the perimeter of the hatch frame.

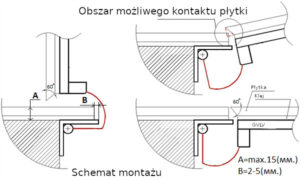

The hatch to the basement is mounted in a prepared hole of the appropriate size for the hatch (see installation). The surface of the cover should be in line with the floor on which the tiles will be glued; “ears” for fastenings are welded into the structure around the perimeter of the frame, through the holes of which the hatch is fixed in the opening using anchors. The gap around the frame must be sealed with foam. Before facing, treat the cover plate with a deep penetration primer. The tiles are glued strictly according to the recommendations in the drawing (see installation)

Today, a floor hatch with an electric lift is an ideal solution for country houses where it is necessary to preserve the usable area of the room, preserve the interior design of the room and gain comfortable access to the necessary premises. Also, floor hatches are often used in non-residential premises, such as a warehouse, garage or store.