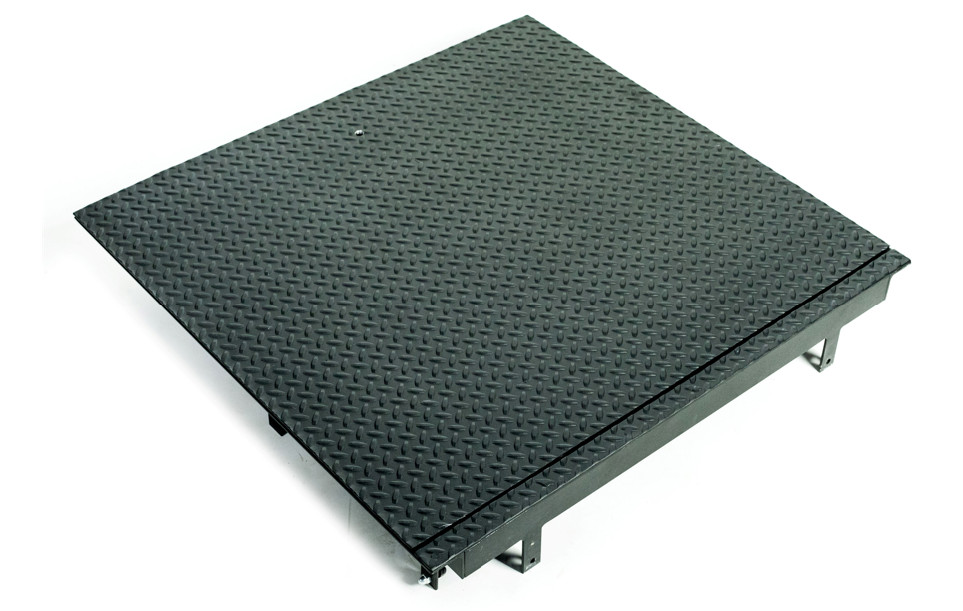

Floor hatch model “Standard”

The hatch is a technological structure designed for access to communications in the floor and also for moving to the basement or cellar. Thanks to its sealing of the lid, the hatch can be installed both indoors and outdoors. The floor hatches of this model have two shock absorbers in their design, which lift the cover upward, thereby facilitating opening.

Application of hatches of the “Standard” model

Floor hatches of the “Standard” model are floor hatches mainly for outdoor use. The “Standard” model is a ready-made

metal structure that is ready for use without any additional processes of tiling,

porcelain stoneware, etc. The hatch cover can withstand heavy loads, which allows not only a person to walk on it, but also withstands the weight of a car.

Advantages of “Standard” floor hatches:

– Production of individual sizes in the shortest possible time

– High pressure gas shock absorbers for lifting the lid

– Latch lock for closing the lid

– Stainless steel plug to prevent moisture from entering the key holes

– Corrugated sheet metal 4mm thick.

– Rubber seals around the perimeter of the hatch cover for complete sealing

– Anti-corrosion painting of the metal parts of the hatch

– Stiffening ribs around the perimeter of the cover

– 60 month warranty.

Hatch design

The floor hatch of the “Standard” model consists of a frame – a metal corner, a cover – a profile pipe and a corrugated sheet,

two gas shock absorbers, which are selected individually to the size of the hatch, a stainless steel plug that fits tightly

to the cover, a latch lock and a key for opening the hatch. The hatch is manufactured using MIG\MAG welding while maintaining the most accurate dimensions of the structure. The hatch is painted with anti-corrosion powder paint to avoid rust in high humidity environments. The lid can be easily opened with a key and raised by gas shock absorbers; the hatch is closed by pressing until the lock clicks into the lid.