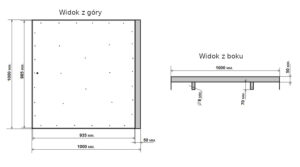

Floor hatch under tiles with gas shock absorbers, “Light+” model.

The Light+ model greatly facilitates daily transitions between floors. The difference from the previous model is the presence of insulation – such a hatch does not have a negative impact on the temperature regime of the room. This model is intended for indoor use, has an improved design and a convenient lightweight lid. When installing it, the usable area of the room does not suffer, since we have provided for the need for tiling. After installation, you can safely walk on it, and unknowing people will not even notice the presence of an invisibility hatch.

Design of an insulated floor hatch

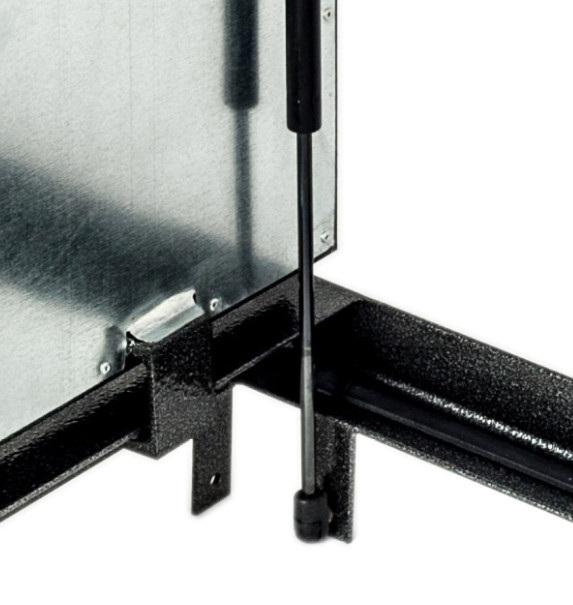

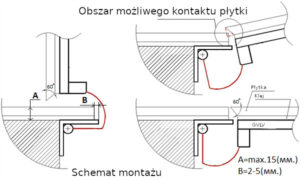

The main parts of the hatch include its frame and cover. The structures of hatches to the basement are made of high-quality thick-walled metal through welding. The completed frames are coated with enamel paint with pronounced anti-corrosion properties. A slab of gypsum fiber moisture-resistant sheets is already screwed to the hatch cover and is ready for cladding work. Opening and closing of the unit is carried out softly and almost silently thanks to the improved design of gas shock absorbers. We carefully select them for each type of hatch, taking into account the dimensions of all parts, the required pressure force and weight. For safe opening, floor hatches on shock absorbers are equipped with limiting loops – the structure stops when it reaches a certain angle. You don’t have to worry about damaging the tiles by abruptly opening the structure. Accordingly, the shock absorbers themselves will last much longer – the risk of their rupture is minimized.

It’s no secret that the hatch into the basement must be strong and durable, for this we strengthened its cover with spacers. As a result, the client receives a hatch that is as rigid as possible and resistant to external influences, which is not afraid of loads. Despite the large dimensions of some hatches, they all open quite smoothly using a four-sided key and a latch lock. The floor hatch is closed by simply pressing the hatch cover against the frame. Despite the ease of closing, the cellar hatch is sealed due to the use of high-quality rubber seals. They will last for many years without stretching or blowing, which is very important for a cellar hatch. Another important advantage of the Light+ class model is that it is equipped with limiting loops to prevent the formation of tile chips along the contours of the hatch.

Advantages of Light+ class floor hatches

• Easy to install the structure – the “Installation” tab describes step-by-step instructions of 5 points, which will not be difficult to implement. The presence of “ears” for fastening dowels and anchors facilitates the fixation process;

• The cover is designed for facing with ceramic tiles and laminate, so you can make the transition between floors (or access to revisions) completely invisible;

• Insulation prevents drafts and condensation;

• The resistance of the structure to loads allows its use in technical rooms, garages and factory workshops, which greatly saves work space;

In our online store you can buy floor hatches for the basement or order production according to individual parameters. Their cost is calculated based on the dimensions, materials used and additional options. All structures are made from high-quality raw materials and are protected from corrosion and mechanical damage.