Description of the “Optimal” hatch

The “Optimal” floor hatch is a revision model of hidden installation and is placed directly into the floor or ceiling. Invisible hatches of the “Optimal” type are self-lifting hatches on gas shock absorbers, which work to provide easy access to all communications located below floor level. These hatches are completely sealed and can easily be used outdoors.

Where are Optimal hatches used?

Floor hatches for “Optimal” type tiles are designed for installation and use both indoors and from the inside. Floor coverings such as linoleum, mosaic, carpet, tiles can be glued to the cover of this product…

Advantages of “Optimal” hatches

-Tightness. Floor hatches of the “Optimal” type are our new development. Their advantage over other similar hatches is their complete tightness.

– Versatility. These hatches can be safely used outdoors and are not afraid of any natural phenomena.

– Withstands heavy loads.

– Easy and quick access to communications.

Design of the “Optimal” hatch

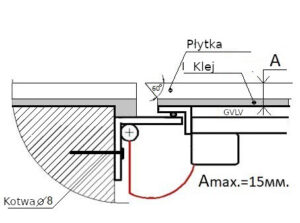

This hatch contains an external frame equipped with a metal corner profile, and in addition a cover frame based on a pipe with a rectangular cut. The outer frame is welded with a square pipe, and the frame itself is reinforced with a welding cross.

A gypsum-fiber moisture-resistant board is screwed to the frame of the hatch cover with self-tapping screws, and parts of the floor covering are already glued to it.