How to choose a hatch for tiles?

When planning to make repairs, almost everyone is faced with the need to correctly select and install technological equipment. Currently, preference is given to the hidden placement of such devices, which in turn creates the problem of ensuring free access to it. Devices, communications, shut-off valves and everything else hidden in walls, ceilings or floors most often require periodic inspection, maintenance and repair, and to carry out these routine actions without problems, you need convenient hatches that can be disguised.

Types of hatches

Hatches can be divided into several main types, differing in design and purpose. If the hatch needs to be installed on a plain painted or wallpapered surface, then you can use so-called paintable hatches. With them, all problems are solved by choosing the appropriate paint compositions or wallpaper with which they can be pasted over. Such products are convenient to use in rooms finished with plasterboard systems.

The second type, which is subject to more serious requirements, is floor hatches. The name itself shows the main problem that has to be solved when installing such a product on the floor surface. First of all, it is high strength and the ability to withstand heavy weight.

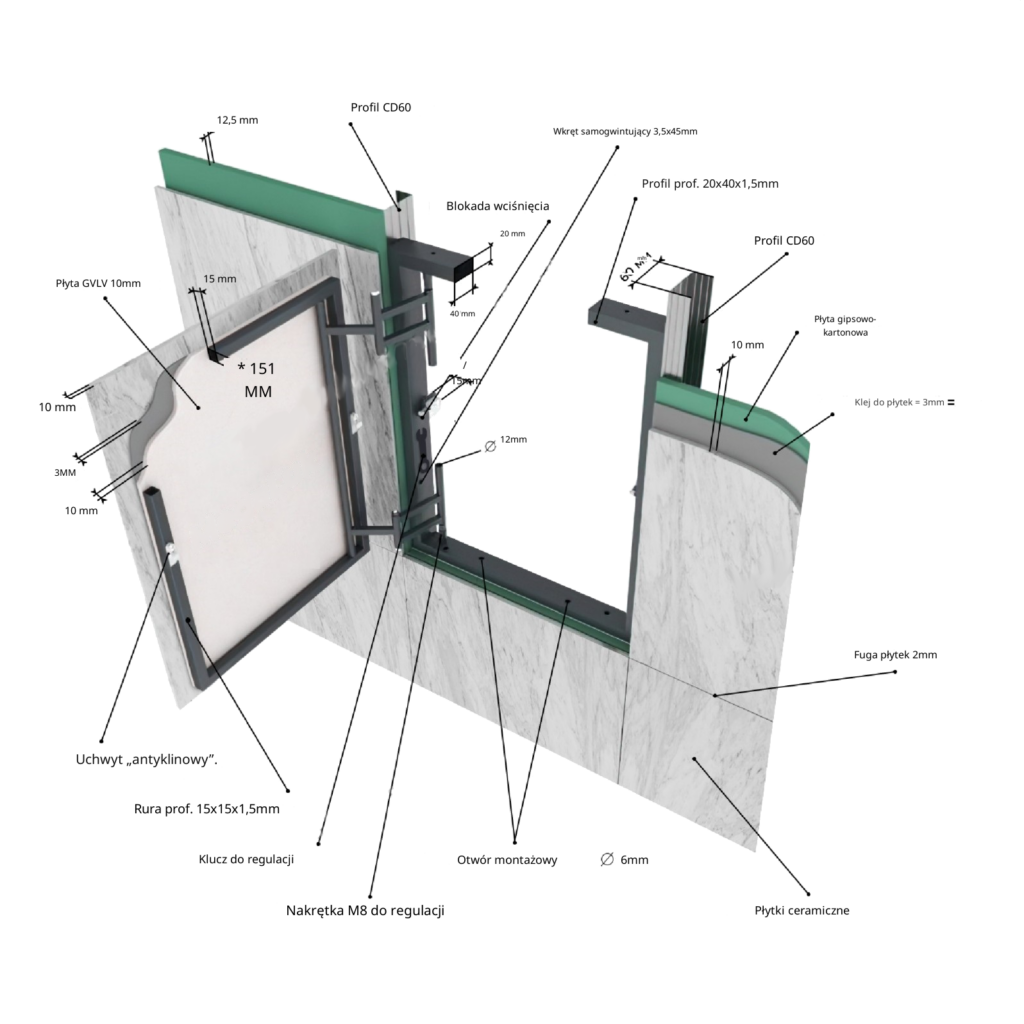

And the third type is tile hatches. They perfectly fulfill their main task, hiding what is behind them, and at the same time providing quick and easy access. The main design element is the frame mechanism, the production of which uses aluminum profiles or tubular steel. If the hatch mechanism is subject to serious loads, then preference is given to steel, but in other cases aluminum parts are more often used, since this material does not rust when exposed to moisture. A cover is installed on the frame, the method of fastening of which is determined by the design of the model. The outer surface of the door is covered with a technological layer of moisture-resistant plasterboard or gypsum fiber.

Models, their characteristics and advantages

There are five main types of hatches, each of which has its own advantages:

- pressure hatches

- “Inspector”

- folding

- swing

- two-door

- sliding

For use as a traditional inspection hatch, push-on hatches are ideal; moreover, if you carefully select the dimensions and carefully install them, they become almost completely invisible, especially if you seal the seams with silicone sealant. Push locks securely fix the door, preventing it from opening or falling out spontaneously. In order to open such a hatch, no special devices are needed. Lightly pressing the cover triggers the mechanical latch, as a result of which the cover moves out of the opening and can then be moved to the side without the risk of damaging the facing material.

The “Inspector” model goes well with any surface, including those covered with ceramic tiles, wallpapered or painted with any coloring compositions, as well as trimmed with other materials, such as a mirror. It allows you to preserve the existing structure and surface pattern, has high strength, which allows you to use building materials with a high mass for finishing.

The push and “inspector” models are distinguished by their high strength and reliability of two-link, non-sagging hatch hinges, which allow precise adjustment to achieve the optimal location of the door relative to the frame. The lid is covered with a moisture-resistant gypsum fiber board, which allows any finishing materials, including heavy ceramic tiles, to be securely fixed to its surface. Metal structural elements are painted with hammer enamel to prevent corrosion. All elements of the product are manufactured with high precision, which guarantees long service without the need for repairs and maintenance.

Hinged hatches for tiles are also quite popular. They have almost the same characteristics as push ones, with the exception of restrictions on the use of facing material and the method of opening the door. To do this, you will have to use suction cups, which means the material with which the lid will be lined must be smooth.

Sliding hatches under tiles can also be classified as push-type hatches based on the opening method. Their design allows the products to be used in hard-to-reach places.

Tilting hatches are also used in places where it is impossible to use other hatches due to their design features. Opening is done using a suction cup, so the facing material on the lid must have a smooth surface.

Two-door hatches are one of the options for a hinged hatch, with the exception of non-standard sizes. This allows them to be used where conventional dimensions do not meet the needs, for example for access to boilers, pumps and other equipment.

Selection rules

In order to buy a pressure hatch, you must follow a certain algorithm. This will allow you to avoid unpleasant surprises and quickly solve the problem. A whole line of hatches with standardized dimensions is produced, and this makes it possible to select them according to the optimal dimensions.

- It is necessary to determine the height and width of the opening to which the hatch should provide access;

- We measure the dimensions of the ceramic tiles that will be used for tiling the room;

- We determine the number of tiles that are needed to completely cover the access area – this will be the opening into which the hatch is installed;

- We measure the length and width of this block made from tiles;

- We select a hatch whose frame dimensions are the same or slightly smaller than the block of tiles, and it is important that the tile protrudes beyond the dimensions of the door by at least 5 millimeters, and on the hinge side by no more than 50. The remaining tiles should be attached to the door by more than 60% of the its area for reliable fixation on the surface of the lid.

Technical characteristics of pressure hatches for tiles:

– Frame\door material : profile steel pipe 40*20*2; 15*15*2; round steel pipe d\12

– Door plate : GVLV (moisture-resistant gypsum fiber sheet)

– Accessories : push locks (with anti-wedge holders) “mini-latch” (made in Europe)

– Assembly method : argon-arc welding.

– Painting : anti-corrosion powder/hammer (made in Europe)

– Opening pattern : swing door (two-link hinges)

– Opening/fixing method : pressing

– Installation method : fastening with self-tapping screws/dowels (holes in frame d\6)

– Equipment : technical .passport

Table of sizes and main parameters of standard push hatches:

| Hatch dimensions (frame) (WxH mm.) | Door dimensions (WxH mm.) | Door load (kg) | Complete hatch weight (kg) |

|---|---|---|---|

| 200x300 | 152x245 | 9 | 2.1 |

| 200x400 | 152x345 | 11 | 2.3 |

| 200x500 | 152x445 | 12 | 2.7 |

| 300x200 | 252x145 | 9 | 2.1 |

| 300x300 | 252x245 | 13 | 2.5 |

| 300x400 | 252x345 | 14 | 3.2 |

| 300x500 | 252x445 | 16 | 3.9 |

| 300x600 | 252x545 | 18 | 4.6 |

| 400x300 | 352x245 | 14 | 3.2 |

| 400x400 | 352x345 | 16 | 3.6 |

| 400x500 | 352x445 | 18 | 4.3 |

| 400x600 | 352x545 | 20 | 5.0 |

| 400x900 | 352x845 | 27 | 10.0 |

| 500x300 | 452x245 | 16 | 3.9 |

| 500x400 | 452x345 | 18 | 4.3 |

| 500x500 | 452x445 | 20 | 6.5 |

| 500x600 | 452x545 | 23 | 7.7 |

| 500x800 | 452x745 | 27 | 10.0 |

| 600x300 | 552x245 | 18 | 4.6 |

| 600x400 | 552x345 | 20 | 5.0 |

| 600x500 | 562x445 | 24 | 8.8 |

| 600x600 | 552x545 | 30 | 12.7 |

| 600x1000 | 552x945 | 32 | 14.0 |