How to install a pressure hatch?

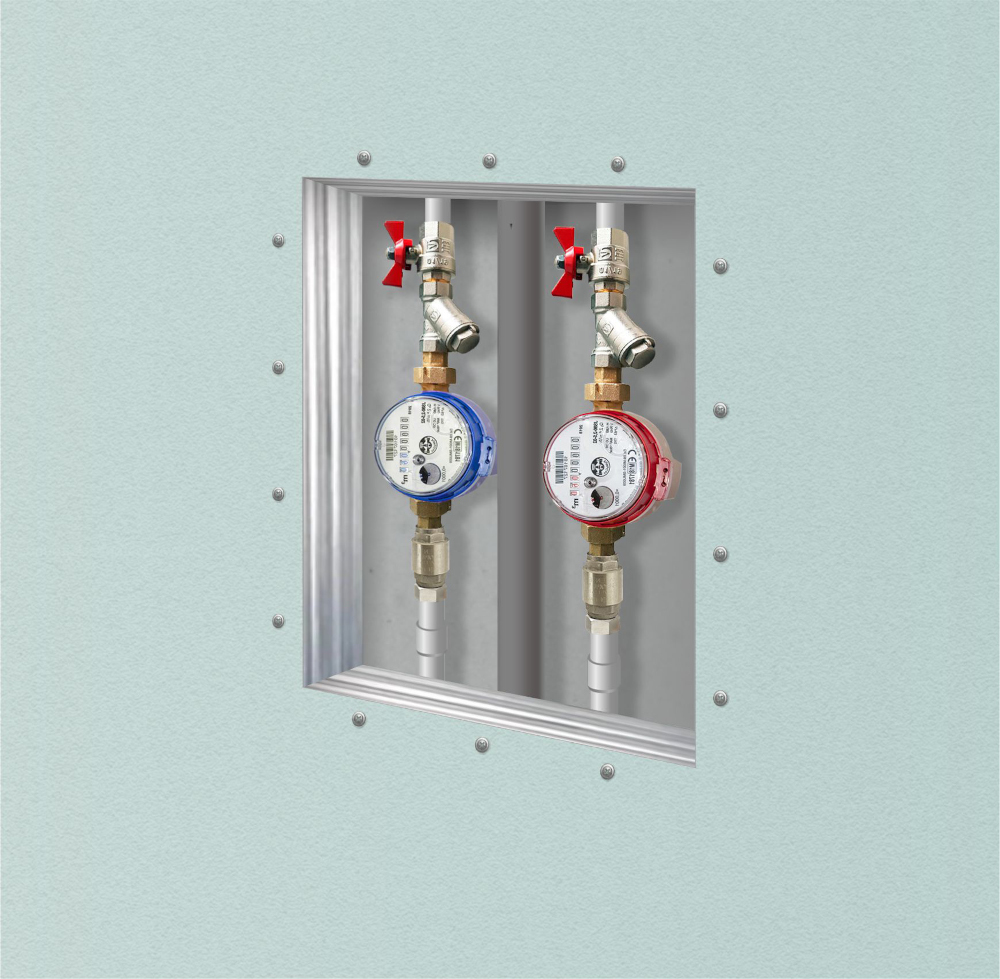

Hatches under tiles are used where it is necessary to disguise the equipment of communications located in the room. This is done both for aesthetic reasons and in order to protect communications from damage. The presence of a hatch provides access to pipes, wires, etc. hidden under the floor, in the walls and on the ceiling. Such inspection hatches under the tiles are distinguished by the fact that they are invisible, since they are lined in the same way as the surrounding areas.

Installing a hatch under the tiles

Before installing a hidden hatch, you need to know its structure. The material for the frame mechanism is tubular steel.

A cover is included with the hidden hatch frame. Its base consists of the same metal as the frame mechanism. To finish the outer covering of the lid, moisture-resistant gypsum fiber GVLV is used. It is these materials that the tile finish is applied to.

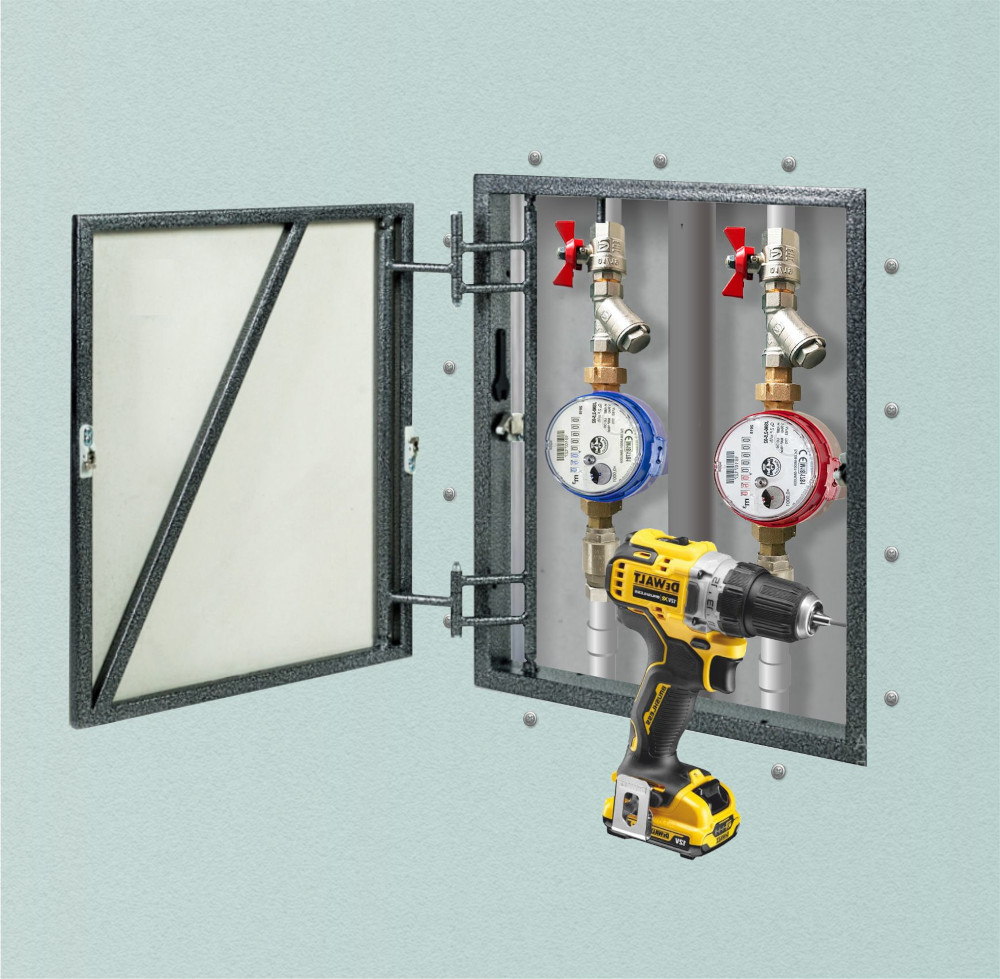

The version with a sliding sunroof differs in that it is equipped not with a standard, but with a three-link hinge design. Thanks to this solution, the lid opens not only frontally, but also laterally. The hinges are capable of adjusting several positions of the lid. The structure is painted with powder enamel, which will provide anti-corrosion protection. The hatch is equipped with reliable fittings.

When choosing the size of a hidden hatch for tiles, it is better to be guided by the dimensions of the finishing material. For example, with a tile size of 60×30 cm, the same hatch parameters are best suited. The dimensions are determined by the size of the frame; the dimensions of the tiled door should be slightly inferior to it. This is necessary for a perfect match between the tiles and the joints, which ensures an aesthetically pleasing appearance of the hatch after installation.

After choosing the dimensions, you should think about a solid foundation for the structure. Typically, a plasterboard box is installed on the edges of a metal frame. However, it is advisable to use a brick or block opening as a stronger base. With this installation method, fastening is carried out using dowels. When connected, the frame and masonry form gaps that are well filled with polyurethane foam. It is important to make the base strong enough so that it does not wobble under any circumstances.

The frame is fastened with long self-tapping screws. The holes for them are drilled in the metal in advance. The profile planes for the frame and the plasterboard box must coincide. Then the structure should be sheathed with overlapping plasterboard material.

Then comes priming and tiling. When covering pressure hatches with tiles , you should block the pressure mechanism using wedges so that the lid does not open during finishing.

For the full effect of invisibility, it is recommended to silicone the seams along the edge of the door and cut through the silicone at an angle of 45 degrees

Installation instructions for the "Push" model hatch:

Sound insulation and seam sealing.

Be careful to fill the seams along the contour of the hatch door for push-type models only to the thickness of the ceramic tiles. To activate the push locks and open the door - do not allow sealant to get under the tiles!

Table of sizes and main parameters of standard push hatches:

| Hatch dimensions (frame) (WxH mm.) | Door dimensions (WxH mm.) | Door load (kg) | Complete hatch weight (kg) |

|---|---|---|---|

| 200x300 | 152x245 | 9 | 2.1 |

| 200x400 | 152x345 | 11 | 2.3 |

| 200x500 | 152x445 | 12 | 2.7 |

| 300x200 | 252x145 | 9 | 2.1 |

| 300x300 | 252x245 | 13 | 2.5 |

| 300x400 | 252x345 | 14 | 3.2 |

| 300x500 | 252x445 | 16 | 3.9 |

| 300x600 | 252x545 | 18 | 4.6 |

| 400x300 | 352x245 | 14 | 3.2 |

| 400x400 | 352x345 | 16 | 3.6 |

| 400x500 | 352x445 | 18 | 4.3 |

| 400x600 | 352x545 | 20 | 5.0 |

| 400x900 | 352x845 | 27 | 10.0 |

| 500x300 | 452x245 | 16 | 3.9 |

| 500x400 | 452x345 | 18 | 4.3 |

| 500x500 | 452x445 | 20 | 6.5 |

| 500x600 | 452x545 | 23 | 7.7 |

| 500x800 | 452x745 | 27 | 10.0 |

| 600x300 | 552x245 | 18 | 4.6 |

| 600x400 | 552x345 | 20 | 5.0 |

| 600x500 | 562x445 | 24 | 8.8 |

| 600x600 | 552x545 | 30 | 12.7 |

| 600x1000 | 552x945 | 32 | 14.0 |